فولادسازی، آهنگری و عملیات حرارتی

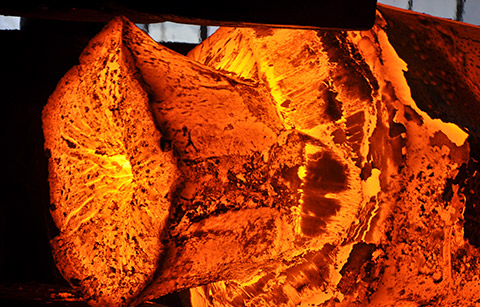

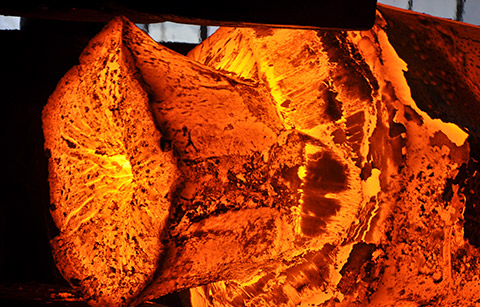

Casting

The casting section of Machine Sazi Arak Co. Metallurgy Group using electric arc furnaces, LF, VODC (Vacuum Oxygen Decarburization Convertor), one of the most advanced methods of steel refinement, is capable of producing carbon steel, low-alloy and high-alloy steel and special steels such as stainless and refractory steels of high qualities and following properties:

- High purity

- Hydrogen content less than 2.5 ppm

- Nitrogen less than 50 ppm

- Sulphur less than 0.007%

- Carbon less than 0.03%

- Resistance to high corrosion

- High weld ability

- Improved machining properties

- Improved mechanical properties

Flange

MSA metallurgy production group employing first-rate services of forging equipment such as hydraulic hammers, presses, ring rolling machines and research and laboratory facilities is one of the greatest manufacturers of high pressure flanges used in oil and gas industries and low pressure water flanges as per the latest universally acknowledged standards.

Also, this group which has advanced equipment in steel melting/making workshops including vacuum melt filtration convertor can produce a variety of carbon, stainless, alloy steels with high strength and resistance to corrosion in sour environments containing H2S in different conditions and requirements on the basis of NACE MR0175/IS015156 standard (HIC, SSCC-resistant) for the production of flanges with forging method.

Moreover, the flanges produced in metallurgy production group are brought under different heat treatment processes such as normalizing, annealing, quenching and tempering to meet the mechanical properties of the desired standards.

Standards used for the dimensions and design of various flanges based on size and pressure class:

Anchor flanges

Anchor flanges are among main parts of oil and gas pipelines carrying high pressure fluids and MSA metallurgy production group, possessing the required technological capabilities, knowledge and equipment, is the manufacturer of these parts in different sizes up to 56" made of carbon steel and micro-alloy steels such as ASTM A105 and all grades of ASTM A694. All design and production stages and hydrostatic tests such as RT, MT, and UT are accomplished as per the referenced standards such as the standard of : NIGCASME Sec.VIII DIV.1-IGS-M-PL-027 or PLD 108.

Industrial Rings and Bushes

Various industrial rings and bushes used in oil, gas and other industries are produced in MSA metallurgy production group in different sizes as per the customer specifications and requirements. These parts are produced with modern ring rolling machines using hot rolling method and 1600- ton press employing mandreling method. All forgeable materials such as carbon steel, stainless steel and other UH alloy steels are used in the production of these items as per EN10025, DIN17350, EN10083 standard and/or any other standards required by customers under the general standard of open die forging DIN7527.

Railway Tires

Railway tires are among routine products of MSA metallurgy production group. Different production stages of which consist of steel making, ingot casting, cutting, forging, rolling, heat treatment, shot blasting and packing delivered to customers as normalized forgings.

Different mechanical tests such as tensile, impact, and hardness tests, macroscopic and microscopic structural examinations,100% ultrasonic tests along with constant inspections and controls during production processes emphasized in the related QC plan are all measures taken to ensure high quality of the products.

Steel Parts and Sections

Steel sections/segments such as plain and stepped sections, round and square bars, steel blocks and other special sections are produced in this production group using open die forging technique. All forgeable materials such as carbon steel, stainless steel and high alloy steels are used in the production of these items as per EN10025, DIN17350, EN10083 and/or any other standards required by customers under the general standard of open die forging DIN7527.

Wellhead Equipment

Different types of equipment such as gate valves, spools, solid blocks, and B.O.P (blowout preventers) are produced in MSA metallurgy production group as per API6A standard. These products are made of low alloy steel AISI 4130 and martensitic stainless steel in the production of which all resistance to corrosion requirements, mechanical properties and required tests have been accomplished as per NACE MR0175 and API6A standards.

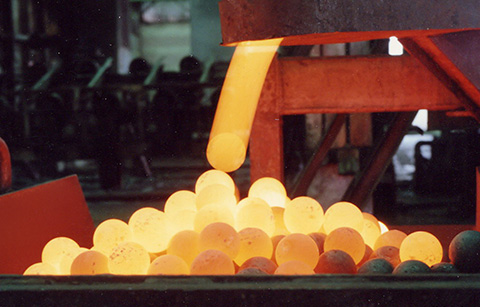

Steel Balls

MSA metallurgy production group, the first manufacturer of steel grinding balls, enjoying its exclusive equipment facilities in steel making, forging and rolling, is actively involved in producing steel grinding balls used in copper, iron ore, cement, coal, phosphate, and gold mines/industries and aeronautic structures etc. as per the latest well-known international standards up to 100 mm. in dia. Using rolling and from 100 mm. to 300 mm. dia. using die forging. Forging Balls Specification: -High impact and friction resistance properties -Appropriate, unvarying surface & volumetric hardness -Fine martensitic structure -Fully rounded with suitable tolerances