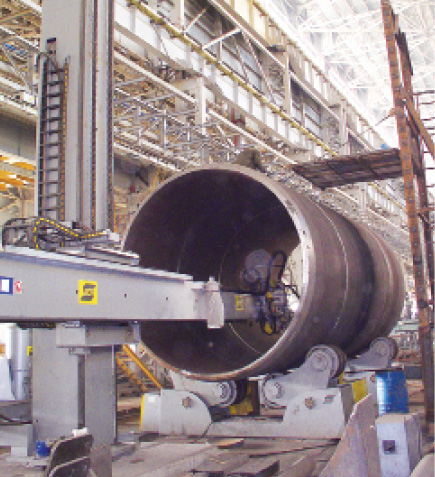

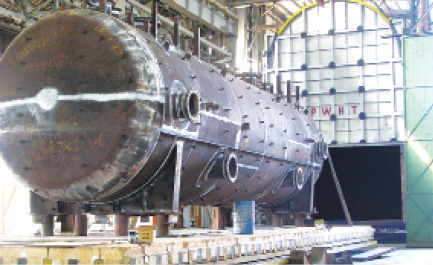

This group of MSA Co. with more than 25 years experiences, skill and technical knowledge of experts and using advanced equipment and machineries in an area of 32424 square meters of covered space and a workforce of 458 people is busy in field of oil, gas, refinery and petrochemical equipment and dam and power plant equipment.

Some products in this group include: Horizontal and vertical pressure vessels, twin storage tanks, LPG storage fixed tanks, LPG portable tanks, fixed and floating roof storage tanks, third methanol converter, refineries and petrochemical distillation towers, heaters indirect gas, heat exchangers, gas filters separators, dry gas filter, Shahid Rajaee power plant chimney with a height of 220 meters, Karun 3 Power Plant equipment, vertical and radial gates, spillway radial gates of Masjed Soleiman Dam, bifurcation with a diameter of 9.5 meter, steel lining of tunnels with a diameter of 9 meter with unconventional sections.Spread in a ground of 33000 square meters of workshop area and over 40 years of experience behind it and employing skilled and specialist manpower, MSA Equipment Manufacturing Group has been able to play a significant role in the area of design, fabrication of refinery equipment as well as petrochemical, gas, power plant, dam, cement, mine and etc. Participation of Equipment Manufacturing Group in South Pars Gas Field Development Project Phases 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 15, 16, 17, 18, 20, 21 and attendance of MSA as one of the Consortium members executing Phase 14 is considered as a reliable pivot point in heavy industry as well as growing move of this manufacturing group forward. Workshop facilities

Rolling Machine Heavy steel shop

Download our catalogue for more detailed information |