Machine Sazi Arak Co. for the first time in Iran has manufactured hot water and steam boilers under the license of john Thompson Co. (England) and now has over 40 years' experience in designing and fabrication of steam and hot water boilers. Radiography, ultrasonic and penetrate liquid test is always applying by the supervision of quality control (QC) inspector s on the welding lines. The boiler structure would be hold in a stress relieving furnace in temperature of 600± 20°C for reaching to a steady molecular structure and deletion of reminder stress. Hydrostatic test would be done based on BS2790 standard and 1.5 times more than designed pressure after tubing. In final step the burner will be tested about 24 hours. The quality and standard certificates are issued for each boiler after check in all contra hollers and indicators.

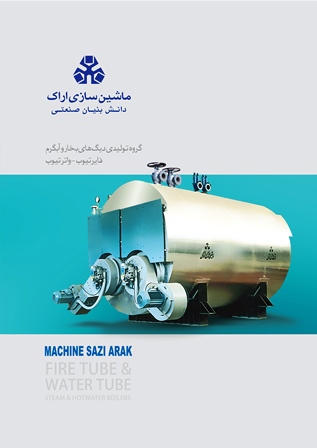

Fire Tube Steam Boilers and Hot Water Boilers

In this type of boilers, the combustion products are transported through the furnace into the pipes intended for heat transfer and transfers their thermal energy to the water that drains these pipes. These boilers are Wet Back and Dry Back, which, according to the customer's request are produces with capacity of 1000 pounds per hour up to 120,000 pounds per hour to a working pressure of 450 pounds per square inch. Mobile Steam boilers

Mobile boilers produce in various sizes and pressures according to the order of industries such as road construction, rubber, mines, concrete processing, especially in cold areas, oil pipelines and industries, airplanes, accident disaster headquarters during natural disasters and also emergency boilers are used when major repairs to various industries, especially foodstuffs. This type of boiler due to the ability to move to different locations for cross-sectional and short-term applications, without the need for road escorts, and independence on additional facilities such as water and gas and urban gas and use of diesel generator have relative advantages, which makes it possible to achieve saturated vapor in a safety and reliability manner.

Corrugate in fire tubes furnaces

Due to the fact that the boiler furnaces are the place of combustion of fuel and the output of the burner, the furnace temperature will increase to a large extent, which will increase the temperature of the furnace's thermal expansion in the direction of the furnace length (due to the relatively long length of the furnace). In the absence of inhibition of this longitudinal expansion, unintentional stresses on other boiler parts, such as tube plates and boiler, will be done. The corrugated furnace is a solution that is suitable for inhibiting this expansion from other corrugate properties.

Water tube steam boilers

With the growing development of various industries and need for higher-pressure steam boilers, use of water tube steam boilers was inevitable. Due to the lack of sufficient production of this kind of boilers for domestic firms and high demand of customers and their referral to foreign companies, MSA began to design this kind of stream boilers besides production of fire tube boilers and steam generators of the HRSG power plant. Now MSA has produces water tube steam boilers in three types of O-Type, A- Type, D-Type, which builds on a variety of capacities and pressures combined with super heater and economizer, either in the form of a package or installation.

Combined steam boilers

Combined steam boilers are fire tube steam boilers with water tube combustion chamber which, like other conventional boilers, have furnace and heat transfer in two stages.

HRSG Combined Cycle Boilers

Combined Heat Cycle Boilers or Heat Recovery Steam Generator (HRSG) is used in power plants to generate electricity and produce higher fuel efficiency. Hot gas from the gas turbines, which is about 550-560 C is passed through the equipment and convert water to steam. The resulting steam is simply used to turn the steam turbines for power generation.

Download Boilers catalogue

|